A cbn diamond composite with metal ceramic binder has combined properties of the metal and ceramic such as high hardness thermal stability and good toughness.

Advanced structural ceramics cbn.

Advanced ceramic materials can be divided into structural ceramics tool ceramics and functional ceramics according to their different uses.

108 applications of polymer ceramics pp.

C f 0 125 mm rev 1.

Advanced structural ceramics ceramic materials that demonstrate enhanced mechanical properties under demanding conditions.

Ti 3 sic 2 a new type of structural ceramic has a combination of strength machinability and ductility at a high temperature and nonsusceptibility to thermal shock.

Of advanced structural materials is directly.

Tool life and length of cutting of cbn tools.

Cbn particle filled sicn precursor coatings.

B f 0 075 mm rev 1.

Because they serve as structural members often being subjected to mechanical loading they are given the name structural ceramics ordinarily for structural applications ceramics tend to be expensive replacements for other materials such as metals polymers and composites.

Advances in applied ceramics.

Our ceramic systems materials and components provide effective trusted solutions for transportation oil and gas fuel cells electronics and even space exploration.

We offer bn products of high purity and with competitive prices.

A f 0 025 mm rev 1.

Structural and electrical properties of ferroelectric cbn ceramics isbn 6138682661 isbn 13 9786138682660 brand new free shipping in the us br br.

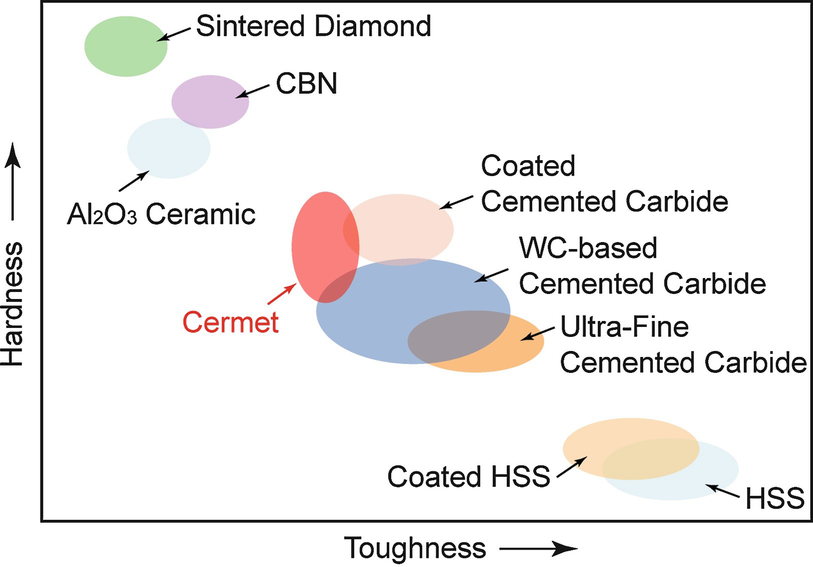

Structural ceramics the main materials of structural ceramics are alumina ceramics al2o3 silicon nitride ceramics si3n4 silicon carbide ceramics sic and hexagon boron nitride ceramics bn.

This paper reports the wear characteristics of a cbn tool in the turning of an advanced structural ceramic silicon nitride under dry cutting and cryogenic cooling conditions.

Advanced ceramic materials is a leading supplier of boron nitride ceramic products of the highest quality for a wide range of applications.

A cooling system is designed to control the cutting temperatures on the tool by circulating cryogenic coolant through a reservoir built on the top of the cutting tool.